Thursday and Friday 23 & 24 October. Parma

We left Bologna Thursday morning and took the train to Parma. Since we were only going to be in Parma for two days, we decided to stay at a hotel, the Hotel Farnese. We ate lunch and roamed around the town which turned out to be really cute. It, like Bologna, is also the home of a major university. Of course we visited another cathedral, a piazza or two, and other historic and important sites in the city, including the shopping area. The weather was really chilly in the morning but by the time we got to Parma, it had warmed up so it was nice to be out walking. We had no plans for Parma except that we had established as a priority, getting out to the parmesan and prosciutto factories if at all possible. We checked with the hotel on tours in the area and as it turned out arranged one with this young lady who really knows her stuff.

Prosciutto at the Hotel Farnese, lunch appetizer on October 23rd. Pasta dishes followed.

Piazza della Pilotta where the National Archaelogical Museum and the Farnese Theatre are housed in what was once a large church and castle. Napoleon ordered destruction of the church and WW II destroyed other elements. The trees on the piazza were planted where the columns of the church once stood

On Friday, Alicia Rossi, a licensed tour guide, took us to a Parma cheese factory, a prosciutto ham factory, the Torrechiara Castle, lunch at a winery, and then a brewery! Needless to say it was a very full day but boy did we have fun. The cheese factory was amazing and we were able to see the whole process of how they make Parmesan cheese. Of course the minute you walk into the factory you are greeted with the fabulous aroma of the cheese in progress. Mouthwatering! As you can see from our photos, we had to wear protective covers, hats and shoes and we did look so adorable.

Our guide Alicia, Fran, Connie and another tourist, David, about to begin the tour of the cheese factory

The process for making the parmesan cheese is really complex. This factory is pretty automated and has machines that do a lot of the heavier work but there is still so much that is done manually and every single day. They have no breaks because cows must be milked every day and you have to use the milk so they make the cheese every single day — no holidays! As our tour guide Alicia said – how do you tell the cows you cannot milk them just because it is Christmas or Easter or whatever! Nope that won’t work. So this is an every day business and they do make a lot of cheese. 2,000 rounds of parmesan every month.

The technicians are searching out the big ball of cheese created in the curdling process. Next they will wrap the cheese cloth around it, cut it in half, and move it to the room where each half will be placed in the plastic and later, steel forms to make the wheel

The parmesan cheese began it’s development from milk, curds and whey about three hours before we arrived. Here the men have just split the big cheese ball and are about to lift it out of the vat for further processing

While we were in the beginning part of the cheese process, they gave each of us a taste of the cheese when it really is still sort of in the milk stage and believe it or not, it tasted real good. It was a little sweet and very flavorful. Hopefully the photos will explain the process somewhat. On top of the process, there was even more about controls, inspections, maintaining quality and being able to maintain the Parmesan consortium seal.

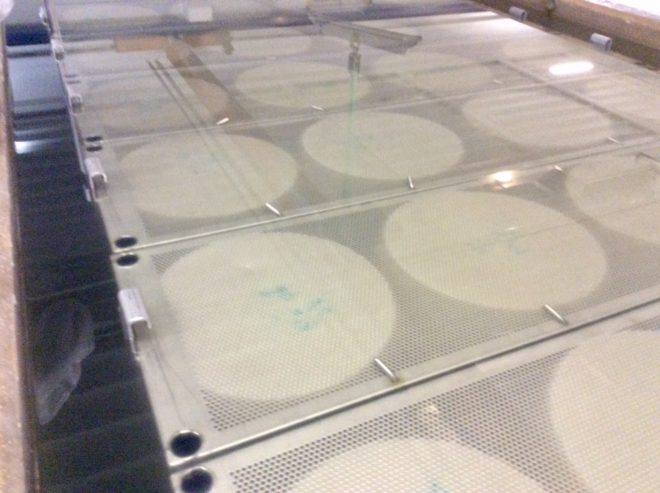

Soft Parmesan balls being lowered into plastic forms used to give the cheese its wheel shape and begin water drainage

After 24 hours, the balls now in the shape of a wheel are wrapped with these perforated stainless steel wraps to enable more water to be pressed from them. The wheels, each of them, is marked with the date and the vat from which it came

After another 24 hours, the cheese in their steel girdles are placed in large tanks of salt water. The salinity level is maintained since the cheese absorbs salt and to keep the absorption even, the wheels are flipped over periodically

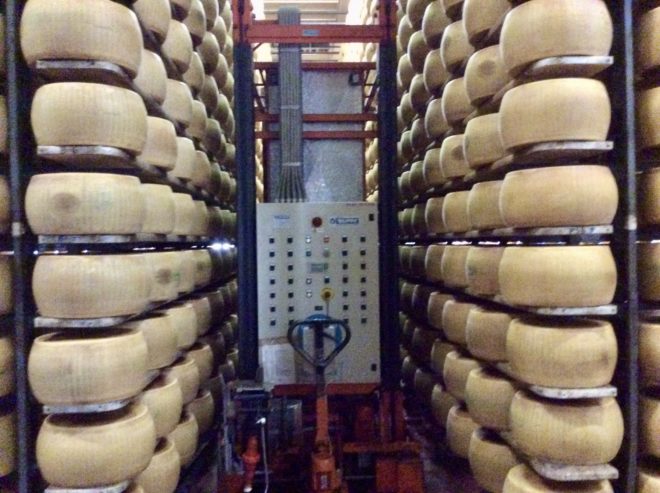

Wheels of different production days stacked on shelves in the storage rooms, lighter color wheels are the newest. This factory produces over 2,000 wheels a month.

This machine travels down the rows of cheese wheels and flips over each one every couple of days — part of the process.

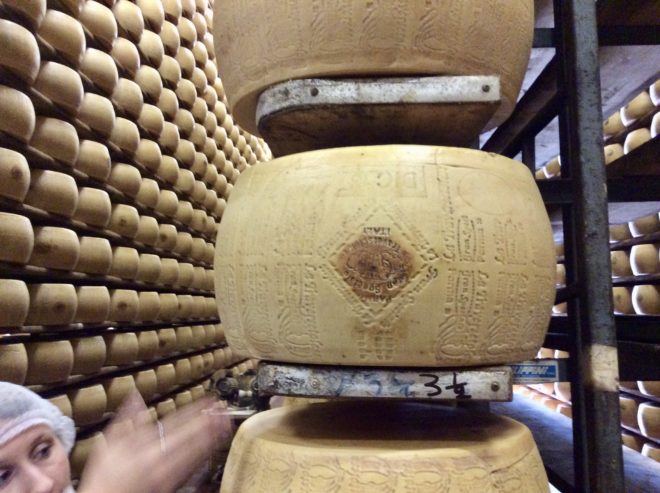

After the cheese has aged a couple of months, the consortium sends out inspectors. If the wheel passes muster, the brand you see is then “fire” stamped on the wheel.

Alicia holds up both a triangle of cheese and two packages of what is called the core. The wheels are cut longitudinally with a wire to make two wheels and then the centers are cut out and sold separately. Cores are the best cheese and cutting the wheels that way, it is also easier to cut the pie shapes without crumbling of the pointy end.

After the Parmesano Reggiano factory, we headed over to one of the several prosciutto factories in the province of Parma — most of them are in the towns of Fontana or Langhirano. We visited the Conti factory. In Langhirano, just about every building is a prosciutto factory. We must have passed at least six or seven on the way up to the Conti facility. Like the cheese, it’s another elaborate process to create the Prosciutto di Parma with official consortium stamp. Here there was some automation, some manual work, and also some magic in a way. One of the key elements of creating the Parma prosciutto is the breezes in this area — breezes which blow across from the Ligurian Sea — that’s over off of Cinque Terre and Corsica. Hopefully the photos will help you visualize the process.

The machine where the ham has just completed the wash and massage steps and is now about to be placed in its wide mesh bag before being salted by hand.

This photo illustrates that the salt really only sits on the top of the ham. It’s not on the bottom or sides, nor will it ever be.

Three cuts come from the large ham: Proscuitto (about one half), Culaccia (bigger cut of the other half) and Fiocchetto, the smaller section of the big hams. This is Fiocchetto hanging in the curing room.

Additional markings on the hams. There are two “Parma” stamps because the ham is often cut in half along the bone and each half would then have the mark showing its certification. Note also the salve or poltice covering what was the open meat area.

The windows which are opened to enable the Parma area breezes to flow over the curing hams. These breezes are part of the secret to the flavor of Prosciutto di Parma

Prosciutti hanging in the curing area of the factory. The prosciutto is checked about once a week to make sure there is no spoiling and that the quality holds fast.

Horse bone used by the consortium inspectors who inserts it into the prosciutto in five different locations to check the quality and that there is no spoiling

Next we were off to the Castello di Torrechiara, one of the best preserved castles in all of Italy. There is quite a story to the castle but the basics are that one Pier Maria Rossi built the castle between 1448 and 1460. He had married when he was 15 years old and then headed off for school and to make his fortune. He turned out to be a brilliant and wealthy man, ultimately owning many properties and building some 20 or so castles around the region. He also managed to fall in love with another woman. It was for this woman he built the Castello di Torrechiara.

Castello di Torrechiara. In this case, torre does not mean tower. The name came from the days when monks squeezed or pressed olives to make olive oil. In Italian, they were applying “torque” to extract the oil and “tor-ka” later became torrechiara.

The countryside around the castle of Torrechiara. In the foreground is the village of Torrechiara which abutts the caste. Note how guards could look down each street to see the enemy if under attack.

One of the four corner towers of the Castello di Torrechiara — and the one which served as the jail or castle keep.

The Golden Room which was actually the bedroom. It depicts quite well the love Rossi had for his lover. Most of the gold leaf was removed by a successor owner of the castle.

Castle tour complete, it was now 1:00 PM so off to a little winery in the hills for lunch. Nice little place, as was the lunch. Half dozen different hams from the region along with about half dozen different wines. There were also two types of pasta for us to use to absorb the wine. Oh, and three different desserts!

After lunch, we headed off to a beer brewery where we received quite an interesting briefing on beers and brewing them. Best of all though, we were able to sample a half dozen of the beers this family produces before ending our day. Don’t worry — Alicia did the driving.

Headed over to the Parma train station Saturday morning and hopped on the train around 10:30. It was a beautiful ride through the countryside and up to Milano. We’ll save reporting on the rest of that day until we start up the Milan-2 journal chapter.

The cheese process sounds very interesting. (Do they need any flexible packaging?) I can almost taste that cheese. Yummmmm. I’ve gained five ponds reading about all the delicious foods. Miss you! Elsie